Configuration

| Model | ZBJ-DP35 |

| Rated Speed | 50~70 PCS/minute, (3000~4200 PCS/hour, on cup size, paper quality and thickness) |

| Paper Cup Size | (mold exchangeable) 10~50 oz bowl, container, cup |

| Raw Material | One or Two side PE film coated paper |

| Suitable paper weight | 170~450 gsm |

| Power Source | 380V 3-phase, 50HZ |

| Total Power | 10KW |

| Working Power | 5kW |

| Total Weight | GW/NW: 3400/3200 KG |

| Pack Size (L*W*H) | 2300 x 1600 x 2000 mm |

| Working Air Source | Air pressure:0.4Mpa; Air Out-put:0.6m³/minute User should BUY Air Compressor |

| Pack Size (L*W*H) | 2300 x 1600 x 2000 mm |

| Working Air Source | Air pressure:0.4Mpa; Air Out-put:0.6m³/minute User should BUY Air Compressor |

| Pack Size (L*W*H) | 2300 x 1600 x 2000 mm |

| Working Air Source | Air pressure:0.4Mpa; Air Out-put:0.6m³/minute User should BUY Air Compressor |

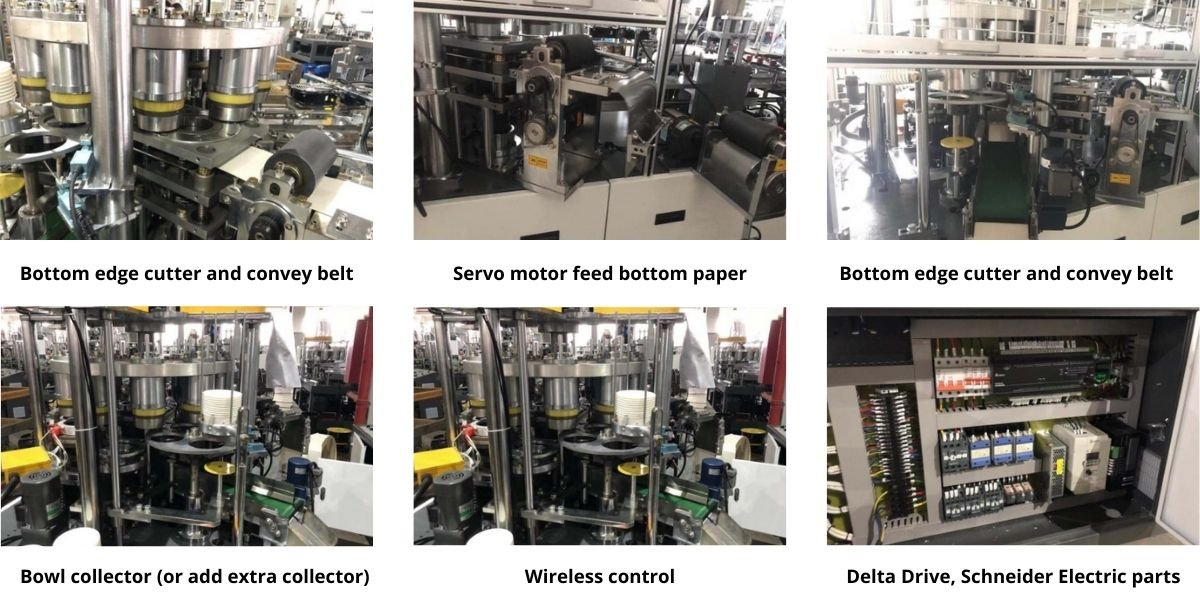

| Cup Side Welding | Ultrasonic System |

| Cup Bottom Heating | Hot air (need air compressor to supply air) |

| Cup Bottom Knurling | Cool Device (recycle water) knurling, for double PE coated paper |

Introdution

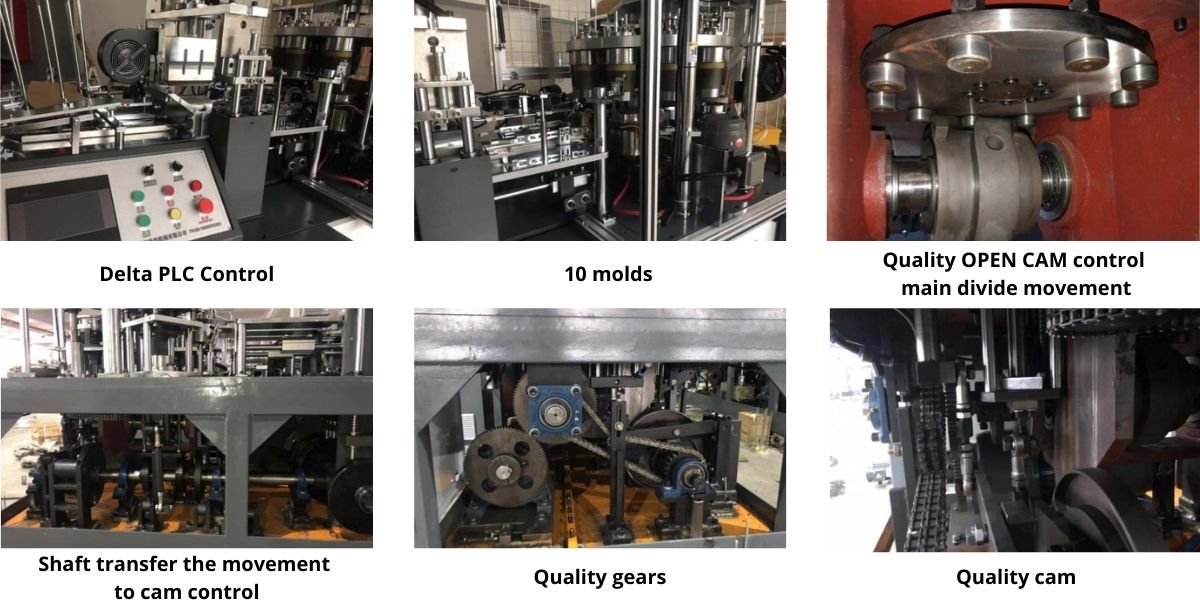

- Adopt Open Cam drive the main table, easy maintenance, more stable and reliable.

- 10 molds instead of 8 molds turn table, more efficient and stable.

- Gears & Axis, shaft, cam control movement, more efficient & accurate.

- HMI & PLC Program computer control, easy operate, fault auto-stop and easy solution.

- All procedure sensor detects (control all step), Less wastage & fault, Reliable.

- Self lubrication (Automatic Oil Lubrication for machine moving part), long life time.

- Import electric Elements, Superior Bearing & Quality material, more durable and reliable.

- Working power only 5 KWH, save electric power cost.

- Product Parameters

- Factory

- Cooperative Partener

Description:

ZBJ-OC35 paper bowl machine, paper container machine, is improved on X35 model, adopt open cam dividing, and use 10 mold instead of 8 mold, fast speed, make big size cup container bowl (for soup bowl, cup, popcorn bowl, container)

Sample:

After Sales Service:

- We offer a 12 months warranty. During the warranty period, we provide free replacement of damaged parts due to quality problems. All failures/breaking caused by improper operation of the buyer and/or normal abrasion are not within the warranty.

- Spare Parts: Each machine has its standard spare parts (see list).

- Manual, Video, to help operate machine, Questions response within 48 hours (except holiday).

- The buyer come to learn how to operate machine, how to adjust, how to change parts. It is free. (buyer should pay for his cost of ticket, hotel, food, etc).

- The seller agrees to dispatch technician for installation & training, the cost covered by the buyer. Technician cost includes: round tickets, accommodation (hotel, food), an allowance of USD100 a day.

Related Product

Poland SanLin Machinery Co., Ltd. is a professional manufacturer of mechanical equipment. The company has strong independent research and development capabilities, and through the standard, refined quality management system, strict quality inspection, the whole process of SPC management, to ensure the high standard of each component.

Our Service

Perfect quality, continuous innovation, quality service, honest customers “are the main purpose of SanLin , because of this, SanLin has a strong growth. In line with the concept of excellence, we have strict control from material selection to manufacturing and after-sales service.

We warmly welcome friends at home and abroad to discuss cooperation.