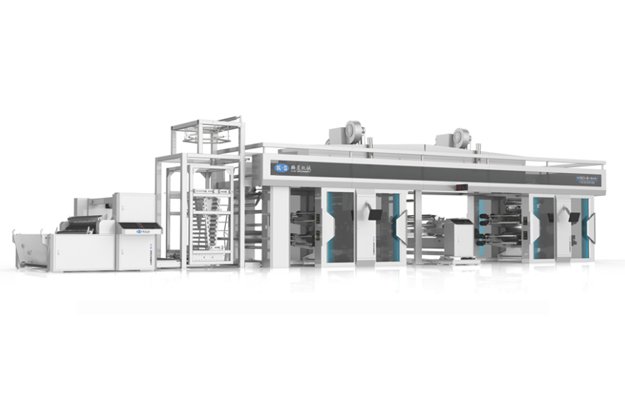

Configuration

| Model | K SCI-EYC-A-850mm | K SCI-EYC-A-1050mm | K SCI-EYC-A-1350mm |

| Raw material width | 800mm | 1000mm | 1300mm |

| Maximum print ing width | 770mm | 970mm | 1270mm |

| Printing color | 4 color(2+2)2、6 color(6+0、3+3)3、8 color(4+4、8+0) | ||

| Printing length range | 345-1350mm | ||

| Raw material di a meter | o1500mm | ||

| Maximum mechanical speed | 50-220m/min | ||

| Maximum print ing speed | 50-200m/min | ||

| Color registration accuracy | ±0.12mm | ||

| Color registration mode | ±0.15mm | ||

| Color registration mode | Vertical:electric or computer automatic color registration2.Horizontal:manual or electric | ||

| Voltage | 3P380V50hz | ||

Introdution

- Printing materials:

- FFS heavy-duty film,plastic film,woven bag,valve bag,paper plastic bag and other flexible packaging roll materials

- Main features:

- The whole machine adopts PLC and variable frequency drive control syste m,

- The unwinding process of the base material and the end face of the fini shed product shall be in order to ensure the stability of the winding proc ess;

- High precision ceramic anilox roller,fully enclosed doctor blade and p neumatic automatic ink pumping system are used for inking;

- The color registration adopts electric registration and pressure contro

- and the HD color still picture monitoring is convenient for the observa tion of printing quality:

- The unwind adopts high-power corona machine for surface material treatm ent to strengthen the printing adhesion so that the ink will not fade;

- The central drum and central big gear are made of high-precision materi als;

- Closed loop constant tension design of high-precision tension sensor en sures accurate and stable printing tension

- Independent hot air electric heating and drying unit,high efficiency a nd energy saving,and heat transfer oil or steam heating mode can also be selected;

- Adjustable reverse printing frame for reverse color adjustment

- The embossing die adopts high-precision alloy abrasives,which has lon g service life and is not easy to be damaged;

- The inserting edge is controlled by stainless steel frame,and the dep th can be adjusted manually according to the product size;

- The rewinding unit can adopt single work position structure (fully auto matic non-stop receiving):3 “or 6″inflatable shaft loading mode

Related Product

Poland SanLin Machinery Co., Ltd. is a professional manufacturer of mechanical equipment. The company has strong independent research and development capabilities, and through the standard, refined quality management system, strict quality inspection, the whole process of SPC management, to ensure the high standard of each component.

Our Service

Perfect quality, continuous innovation, quality service, honest customers “are the main purpose of SanLin, because of this, SanLin has a strong growth. In line with the concept of excellence, we have strict control from material selection to manufacturing and after-sales service.

We warmly welcome friends at home and abroad to discuss cooperation.